Multihead Weigher Packing Machine for Stick Noodles Bean Vermicelli

Application:

Multihead weigher packing machine is equipped with Z conveyer and multihead weigher, it is widely applied to pack solid and bulk products, such as candy, cereal, nuts & snacks, cheese, pasta, beans & rice, pet food & treat, coffee and other non-food products.

Packing Machine Parameter:

Followings are our main packing machine models, you can choose the suitable machine model according to your bag size.

| Model | Filling Range | Bag Size | Packing Speed | Machine Size | Machine Weight | Power |

| P1-420 | 100-1000g | L:80-300mm W:60-200mm | 5-60bags/min. | L1117*W1492*H1532mm | 500kg | 220V,50HZ,2.2KW |

| P1-520 | 100-2000g | L:80-400mm W:60-250mm | 5-50bags/min. | L1217*W1562*H1792mm | 600kg | 220V,50HZ,3 KW |

| P1-720 | 100-5000g | L:80-480mm W:60-350mm | 5-40bags/min. | L1700*W1727*H1950mm | 700kg | 220V,50HZ,3.5KW |

| P1-850 | 100-6000g | L:80-520mm W:60-415mm | 5-30bags.min. | L1800*W1827*H1962mm | 800kg | 220V,50HZ,5KW |

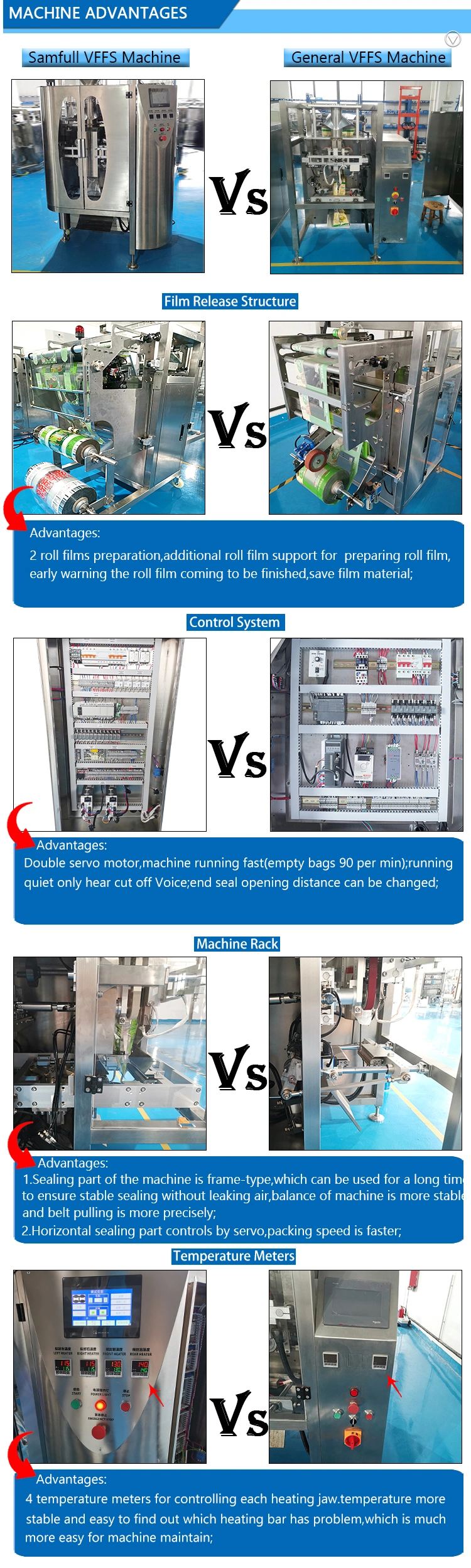

Packing Machine Advantages

1.Schneider PLC computer control system, human-machine touch screen.

2.Accurate positioning, smoothly and stability running.

3.With auto alarm protection function, to minimize the loss.

4.Automatical process of measuring, feeding, filling, bag making, printing.

5.High efficiency and high packing accuracy,about ±0.5-5g deviation

6.Food grade stainless steel 304, safe and durable.

7.Easy to operate and maintain,only need one worker;

8.High packing speed, up to 80 bags per minute.

Optional Functions:

1. Date printer

2. Quad seal bag assembly

3. Bag-in-bag configuration

4. Flat bottom bag assembly

5. Hole punch (Euro slot or round)

6. Load shelf

7. Product settler

8. Gas flush

9. Static elimination

10. Tear notch

11 In-feed and take-away conveyors

12. Integration with variety of printers, metal detectors, label applicators, and checkweighers

About Us